Construction Methods

Heads

All head bases are 3D printed using flexible TPU filament. This material is lightweight, sturdy, and allows for better ventilation. 3D modeling also allows me to easily make changes and adjustments to my current head bases. I can customize any aspect of my head bases to fit your character and vision.

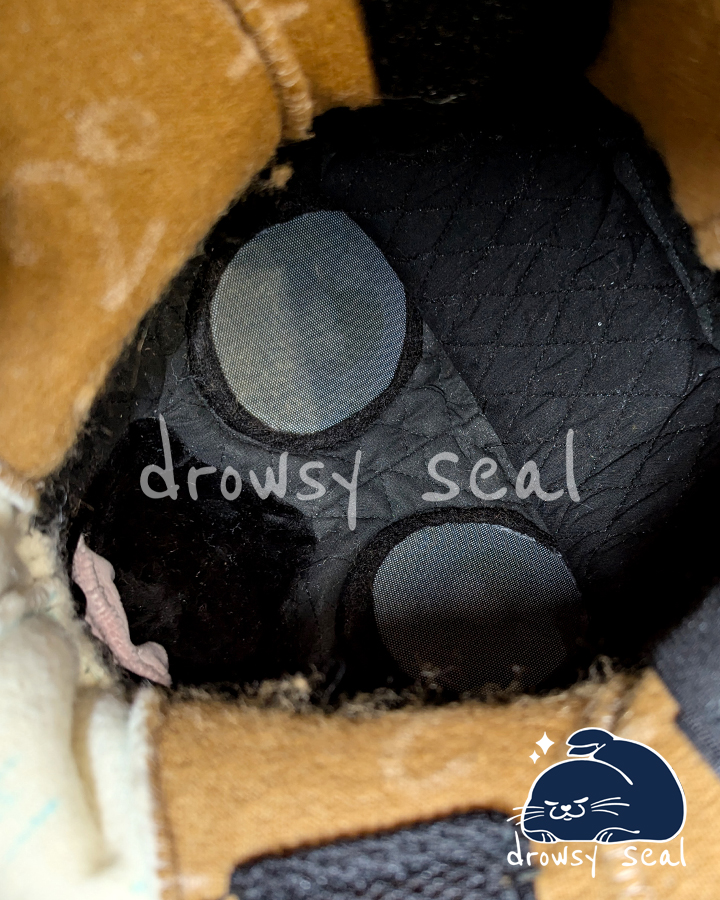

Eye blanks are made of 3D printed PLA+, and the eye designs are dye sublimated onto computer mesh.

As they are hollow, my heads are generally lightweight. Hair, horns, antlers, and other factors can increase the weight of a head, however.

All heads are lined with quilted broadcloth, and are adjustable via wide elastic straps and velcro attached to forehead padding. This technique makes them glasses-friendly by default. I also include a lined zipper on the back of the neck to allow for easy fitting of the head straps.

While I sew as much as I can, some of the details of the suit are glued on. This includes the lips, eyebrows, and eyelashes.

Tongues attach via velcro inside the mouth, and by default are smaller and stick slightly outside of the mouth. I can also make different lengths of tongue, as well as posable ones with wire inside.

I do not make full jawsets, though I can add small fangs.

Hair is an additional option. I use faux fur only (no wigs), and can make hair poofs, mohawks, bangs, and various other front-facing styles. I do not make hairstyles that fully cover the back of the head at this time.

Bodysuits

All bodysuits are padded by default. I do not make straight-legged plantigrade bodysuits.

No DTDs are required! I work off around 20 measurements and 3 photos, and 3D model the bodysuit to your desired shape. I can do almost any kind of shape for your bodysuit, be it padded planti, digi, or something else you can think of.

The front zipper is lined, and necklines are finished with a mochi minky cuff.

Bodysuits are double stitched with a straight stitch, followed by a zigzag for durability and cleanliness. They are machine stitched as much as possible, though smaller markings may need to be hand sewn with a blanket stitch.

Wings can be added to a bodysuit, but they must be smaller and are sewn into the bodysuit. I do not work with magnets for wings.

The default style is a medium sized canine tail, worn with a belt.

All tails have hidden belt sleeves, and tails that zip onto a bodysuit will have belt loops too.

For bodysuits, I highly recommend zip-on tails. They're seamless and make packing and storing much easier. I will only permanently attach smaller nub tails.

Paws

Handpaws have 4 fingers, stuffed with removable pillows filled with polyfil. They are unlined to help with heat, and cuffed at the wrist with mochi minky. All seams are double stitched.

Paw pads are made of mochi minky and are stuffed by default. They are machine stitched into the fingers, not appliqued, for a clean look.

Hooves are similar to handpaws, though the hooves are lined. I only do 3 finger hooves at this time.

Plantigrade feet are the default for full partials. They have a slim ankle, TPU toes, and are lightly stuffed with polyfil.

There are two kinds of soles for feetpaws: outdoor and indoor. Outdoor soles are made of shoe rubber soles that cover the entire bottom of the foot. Indoor soles are made of fur and mochi minky, with stuffed paw pads.

Claws are an additional option, and are made from mochi minky.

Digitigrade feet have a heel and ankle made of a foam shell stuffed with polyfil, and TPU toes. These can be attached via zippers to a bodysuit.

All feetpaws are fully lined with quilted broadcloth, colorfast athletic techno knit fabric, or spacer mesh. They are made without shoes, and have elastic to hold snug to your feet.

I find that in many cases, you can slip your own shoes into the feetpaws as well, if you prefer to wear them that way. Please let me know ahead of time if you're wishing to eventually use your own shoes, so that I can make the paws big enough to accommodate for them.